What Is Lead Time, and How Do You Calculate It?

Everything you need to know about lead time, presented by Replicon, the Time Intelligence® platform

- What Is Lead Time?

- Examples of Lead Time

- What Are the Different Components of Lead Time?

- How to Calculate Lead Time

- What Are the Different Types of Lead Time?

- What Is the Importance of Lead Time in Different Industries?

- How Does Lead Time Affect Business?

- What Impact Does a Longer Lead Time Have?

- How to Reduce Lead Time

- What Is Lead Time?

- Examples of Lead Time

- What Are the Different Components of Lead Time?

- How to Calculate Lead Time

- What Are the Different Types of Lead Time?

- What Is the Importance of Lead Time in Different Industries?

- How Does Lead Time Affect Business?

- What Impact Does a Longer Lead Time Have?

- How to Reduce Lead Time

What Is Lead Time?

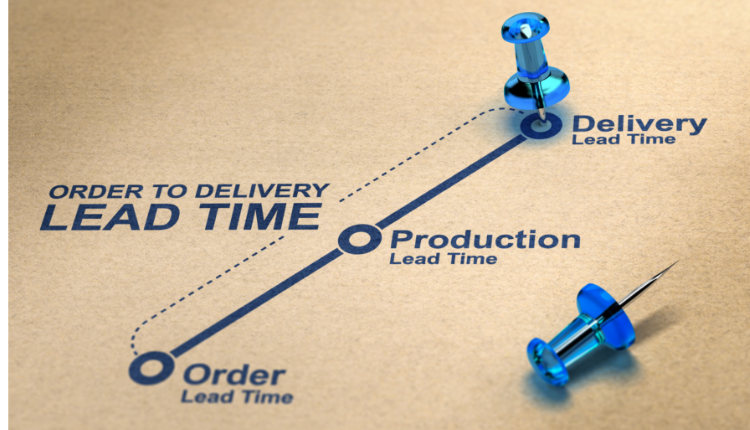

Lead time is the time spent to complete a process from order placement to final delivery. Keeping track of lead time lets businesses determine inefficiencies across the ecosystem and helps streamline operations without any hassles. Accurately calculating lead time is crucial for increasing customer satisfaction, improving production and expediting workflows for faster, smoother deliveries.

Ideally, every business has a lead time. This term is most commonly used in various fields, such as manufacturing, supply chain management, software development, project management, inventory management and more; however, it differs across industries based on the nature of the operation. For example, consider the process of developing new software. Here, the lead time is the time taken to launch software into the market or the time taken to develop, test and deliver a software product. When it comes to inventory management, lead time refers to the time between placing the order for replenishment and receiving it. No matter the size of the business, reducing the time from order to delivery ultimately lets you process more orders and make more money.

Examples of Lead Time

Let’s take a look at an example to understand what a lead time is. Consider a toy manufacturing company that manufactures a toy car. In order to manufacture a toy car, you would be required to procure raw materials and design a frame mold. Let’s assume that it takes a business day for a manufacturer to process the orders, and one business day to procure raw materials and create a frame. And one business day to assemble and make the necessary design. Finally, it takes two business days to ship the toy cars. Each process requires defined pre-processing, processing, and post-processing times to manufacture a toy car.

The pre-processing time is the amount of time needed to process the orders and procure the raw materials.

Pre-processing involves receiving orders from customers and calculating the total number of orders. Further, you need to make sales requests to the production team to manufacture these orders. It normally requires one business day to process the order and procure raw materials.

Processing is the next phase, wherein you understand the time taken to complete the workflow. The processing time is the time involved in manufacturing the orders. It requires roughly 2 business days.

If you offer home delivery to customers, then it will take two business days to transport and deliver the products. This transportation and delivery time is part of the post-processing time.

Now, to calculate the total lead time:

- Pre-processing Time = 1 Day

- Processing Time = 2 Days

- Post-processing Time = 2 Days

- Manufacturing Lead Time= Pre-processing Time + Processing Time + Post-processing Time= 1 Day + 2 Days + 2 Days= 5 Days

Combining all of this, the total lead time taken to manufacture a toy car is five days. This means that you require five days minutes to deliver the final product to customers. Similarly, using this calculation, you can also measure the total lead time, depending on how complex the production process is.

To shorten the lead time, the vendor would need to manufacture additional toys to ship them overnight for delivery.

Why Is Lead Time Important?

Accurately calculating time helps to increase organizational profitability, lets you achieve your deliverables, and keeps your clients satisfied. Even a small process delay can result in compounding delays. Hence, effective planning is critical for improving your lead time.

From order placement to final delivery, lead time plays a pivotal role in an organization. The following are the top reasons why it is important:

Gives a Competitive Edge

Businesses strive to improve their processing times and lead time to gain a competitive edge. Here is an example of how faster lead times improve competitive edge. Consider company A, which offers a certain deliverable in a lead time of 3 days, and company B, which offers the same deliverable in 5 days. It is probable that company A will generate more sales than B. Therefore, customers choose A over B since company A offers the same deliverable in a faster lead time. No matter what industry or business type, lead time helps you gain an advantage over competitors and increase your organization’s profitability.

Maximizes Productivity

Lowering the lead time increases performance, which maximizes your overall revenue. If you are using an agile or waterfall methodology to manage your projects, it is important to have a clear understanding of lead time. In waterfall projects, you cannot begin the next step until the prior phase is complete. When lead times are accurately calculated, you can reduce operational downtime and maximize productivity.

Reduces Downtime and Costs

Calculating the lead time for each step of the process, then streamlining the process is an efficient way to eliminate unplanned downtime. Understanding where your project is most likely to be delayed and eliminating roadblocks will help you improve your lead time. To reduce lead time, set clear expectations and measure the progress at each stage of the project.

Increases Customer Satisfaction

Customer satisfaction is closely related to the fast fulfillment of an order. As the demand for faster fulfillment is increasing, it’s important to deliver projects or services in the stipulated time. To improve your lead time, first, understand the lead time of your business process. Then, create an optimal lead time workflow that helps you complete the process more efficiently and with a shorter lead time. Businesses can move one step closer to increasing customer satisfaction and building customer loyalty by cutting down the lead time.

Improves Forecasting and Decision-making

By streamlining the process from order to delivery and measuring the lead time for each process, businesses can forecast their delivery time accurately. Accurate forecasting makes your customer’s life easier since they will know when their goods will arrive, allowing them to plan ahead and meet their own requirements. Knowing your lead time will help you forecast better, allowing you to optimize inventory levels and prevent the accumulation of unwanted stock.

What Are the Different Components of Lead Time?

Right from pre-processing to the quality-checking stage, here are six components that should be taken into consideration when calculating lead time:

Pre-processing Time:

It refers to the time it takes to receive a request, understand the requirements, and create a purchase order. Pre-processing time is also referred to as planning time

Processing Time:

It’s the amount of time it takes to procure or produce an item once receiving an order

Waiting Time:

It refers to the time spent acquiring raw materials or items to complete the production process

Storage Time:

It refers to the time when the final product is stored in the warehouse until it is transported or shipped

Transportation Time:

It’s the time taken to transport the product from inventory to the customers

Inspection Time:

It’s the time spent by customers checking the product for any defaults or shortcomings after it’s delivered

Total Lead Time = Pre-processing Time + Processing Time + Transportation Time + Storage Time + Inspection Time

How to Calculate Lead Time

Lead time can be calculated using this basic formula: Lead Time (LT) = Order Delivery Date – Order Request Date. However, this formula varies depending on the type of industry. For example, when calculating manufacturing lead time, you should consider factors like pre-processing (planning), processing (procurement and manufacturing) and post-processing (shipping) lead times into account as:

Manufacturing Lead Time = Pre-processing Time + Processing Time + Post-processing Time

And calculating inventory lead times accurately lets you order the right amount of raw materials for your inventory and helps you ensure you have sufficient stock in inventory to fulfill your orders. Therefore, in the context of inventory management, you have to consider supply and reordering delays. The formula for inventory management will be:

Inventory Lead Time = Supply Delay + Reordering Delay

Here’s a practical example to help you better understand the calculation:

Consider company A produces smartwatches, and they receive an order of 20 smartwatches. So, we have to calculate the lead time for an order of 20 smartwatches.

As per the previous manufacturing data, the company can produce 10 smartwatches in a week. It takes roughly a week to procure all the needed raw materials and components to produce these smartwatches. Let’s assume it takes 7 days to get all the raw materials.

Finally, we need to know the shipping time – that is, the time it takes for company A to ship the order from the warehouse to the customer’s address. In this case, it takes one week (7 days) to ship the order.

-

Total Lead Time= Manufacturing Time + Procurement Time + Shipping Time= 14 Days + 7 Days + 7 Days= 28 Days

What Are the Different Types of Lead Time?

Based on the industry, there are four main types:

Customer Lead Time:

It is the time taken from when an order is confirmed to the point it is delivered. Factors including manufacturing processes and shipping methods, along with customer delays, can affect it.

Material Lead Time:

It is the time taken to procure the raw materials required to produce an order. It depends on the supplier’s lead time, transport time, and delays in receiving materials.

Production Lead Time:

It is the time taken to produce a product once all the raw materials have been received. It is also known as factory lead time. This time can be affected by the manufacturing process, machinery downtime, and workforce availability.

Cumulative Lead Time:

It is the sum of the factory and material production time. It refers to the time taken between the confirmation of an order and its delivery to the customer, which includes procuring raw materials and subassembly.

What Is the Importance of Lead Time in Different Industries?

Lead time is a crucial metric in managing projects, inventories, and production supply chains. However, based on the various operations, the exact definition differs across industries as follows:

Supply Chain

In supply chain management, lead time refers to the time required for goods to be delivered from the supplier to the customer. Knowing the lead time for goods is important to make informed decisions about shipping and reordering. Supply chain lead time depends on production time, shipping time and customer time.

Project Management

In project management, lead time refers to the amount of time allocated to a specific task or project. In project management, it is calculated based on task dependencies, such as finish-to-start relationships, where one task must be completed before starting another. In contrast, project lag time refers to the amount of time necessary to complete one task before beginning another. However, both lead and lag times are used when creating a project schedule. This helps project managers meet the deadline by sequencing their activities and tasks.

Production and Manufacturing Industry

A manufacturer’s lead time is the time it takes for a manufacturer to complete an order after a merchant places it. This is also referred to as the amount of time it takes to complete the whole production process, including pre-processing, manufacturing, and post-processing. The time it takes to procure supplies, manufacture, and ship the product is included in this calculation.

Inventory Management

Inventory lead time allows you to estimate demand directly from the market and forecast requirements in advance. Each step in inventory management can be impacted by lead time, resulting in a delay in all operations. By measuring the metric accurately, you can manage your inventory in warehouses and make deliveries on schedule without inventory gaps.

How Does Lead Time Affect Business?

Reducing lead times is an effective way to increase productivity, increase output, and streamline operations. Organizations need to understand the factors affecting them to optimize processes. Here are five common factors:

Unforeseeable Shipment Delays

Delay in shipment is the most common factor that increases the lead time due to unpredictability in weather conditions, unavailability of customers, and other factors. It can be difficult to estimate how long it will take for suppliers to deliver an order. To reduce shipment delays, you can track the movement of orders to handle shipment delays. In order to avoid supply delays from negatively impacting customer satisfaction, contractor dependencies, and cost efficiencies across the board, it is imperative to calculate accurately.

Inefficient Inventory Management

Effective inventory management is an essential element for operating a profitable business. According to a recent case study, inventory management has a positive and significant impact on a company’s profitability. Without efficient inventory management, your business will easily lose track of your stock levels, time, and money. Mismanagement of inventory can result in frequent stockouts, missed sales, and excessive warehousing costs. Hence, it is paramount to reduce the inefficiencies that affect inventory control, to avoid potential issues along the way.

Redundant Processes

By adding unnecessary processes when assembling raw materials into finished products, lead time can increase. Therefore, order completion may take longer than usual, resulting in a lower production rate. Hence, optimizing the process will ensure that there are no unnecessary steps. As an example, if you’re a mobile manufacturing company, it takes more time to complete each order if you have to build every component. Outsourcing pre-assembly is beneficial to optimize production and minimize time.

Variability by Vendor

Lead time is affected by several factors, like communication, non-availability and coordination, that is related to delivery. With lead metrics varying widely from supplier to supplier, it can be challenging to anticipate delivery time for all inventory stock items. In turn, this makes it difficult to coordinate production. Consolidating your suppliers is one of the best ways to ensure on-time production.

Issues With Stock

Whenever a manufacturer or supplier runs out of stock, it is impossible for them to process an order. In such a case, it takes more time to process the order, thereby prolonging the processing time and the lead time. Stock issues negatively affect customers’ satisfaction and processing time. Ultimately, you might be forced to close your business if the situation worsens.

What Impact Does a Longer Lead Time Have?

No matter how great your product or offering is, if you have a longer lead time, customers may look for alternative outlets. Longer lead duration often leads to higher storage costs, inefficiencies, wastage of resources, and, inevitably, lower sales. A business’s bottom line suffers if processing times exceed deadlines. This variability poses a threat to an organization’s profits when customers’ orders are not fulfilled on time.

Therefore, organizations need to assess their processing times to identify ways to improve their efficiency and time. Reducing lead time improves overall productivity, resulting in higher revenues and profits.

How to Reduce Lead Time

Lead times are affected by several unforeseeable factors, including shortages of raw materials, transportation breakdowns, labor shortages, natural disasters, and human error. But you can minimize the risk of delays by following certain steps, as outlined below:

Monitor Supplier Timelines

Partnering with a supplier from overseas is risky since it can take a long time for your order to be accepted and processed. When you choose a local supplier, there is an assurance that you will receive your procurement as soon as possible, thus reducing the lead time.

Keeping tabs on the suppliers throughout the supply chain process helps ensure that expectations are being met and fulfilled on time. Even a short delay can harm a company’s reputation and have an adverse effect on customer satisfaction metrics. Hence it is essential to set clear timelines for your suppliers.

Reduce Unproductive Activities and Standardize Operations

Value stream mapping helps an organization identify activities that don’t add value and that prolong lead times. Eliminating these types of activities helps you standardize and automate your processes and avoid hassles. By standardizing each process of your business, you can reduce risk, maximize efficiency, and improve your bottom line.

Automate Your Inventory Management

Manually entering data and recording purchase orders is a tedious and time-consuming task. Automating your inventory management helps accelerate your replenishment of stock and improve the accuracy of your inventory management. It also simplifies workflows, saves time, and helps organizations monitor inventory in real time. Almost every organization tracks and organizes stock, supplies, and sales using automated inventory management. With an automated inventory management system, an organization can effectively manage its inventory in real-time and can make more informed decisions.

Share Inventory Forecasting Data With Your Supplier

With access to your sales and inventory data, your supplier can anticipate your upcoming orders and can even prepare to ship them ahead of schedule. By gaining visibility across your supply chain, you will be able to work more efficiently with suppliers, reducing lead times.

Frequently Asked Questions

1. What does lead time mean?

Lead time is the amount of time it takes for an order to be delivered to a customer after it is placed. This term is most commonly used in various industries, such as manufacturing, supply chain management, project management, material requirement planning (MRP), enterprise resource planning (ERP), or software development.

2. What is the lead time formula?

Lead time is the time it takes to procure, manufacture, ship, and deliver a product. This can be calculated using a simple formula that varies depending on the industry.

For manufacturers, the formula is written as:

- Total Lead Time = Manufacturing Time + Procurement Time + Shipping Time

- For retailers, the formula is written as:

- Total Lead Time = Procurement Time + Shipping Time

3. What are the types of lead time?

Lead time can be classified into four types: customer, materials, factory/production, and cumulative lead time.